How Flex PCBs Are Changing Electronics Design Today

In the fast-evolving world of modern electronics, innovation isn’t limited to features, size, or speed—it’s deeply rooted in how the product is built from within. One of the most transformative shifts in recent years is the adoption of Flexible Printed Circuit Boards (Flex PCBs). As devices continue to shrink and demand more functionality in smaller spaces, traditional rigid boards are making way for more adaptable and space-efficient designs. Flex PCBs are now at the heart of many modern gadgets, medical instruments, and automotive systems, reshaping what engineers can create.

This evolution goes beyond size reduction. Flex PCBs bring a completely new approach to design that enables curved structures, dynamic movement, and streamlined assembly, fundamentally changing the way engineers think about electronic architecture.

What Are Flex PCBs and Why Are They Unique?

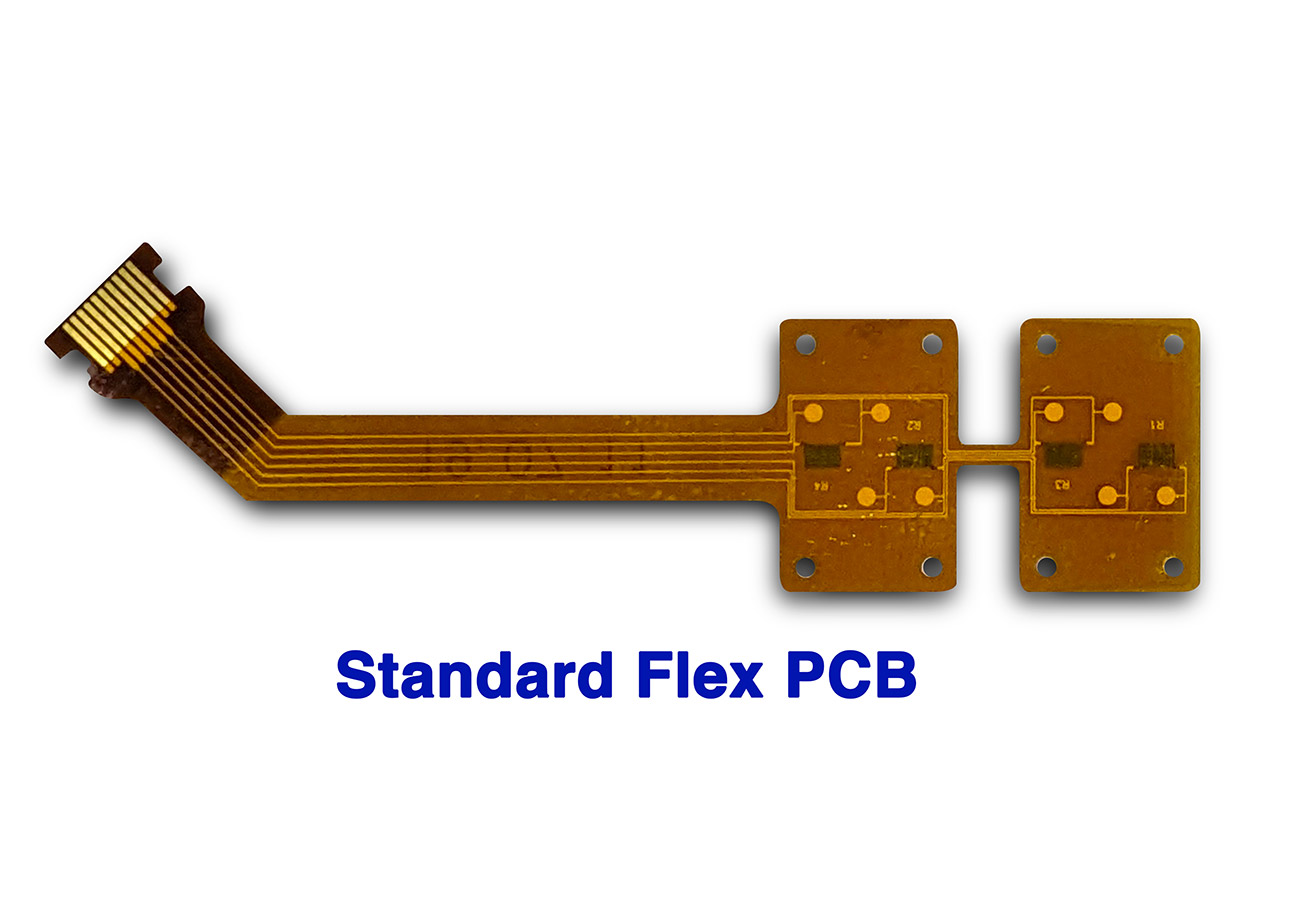

Flex PCBs differ from conventional rigid boards in their material composition and versatility. While traditional PCBs are made from inflexible fiberglass materials, Flex PCBs are fabricated using flexible polymer substrates like polyimide. This flexibility allows them to bend, twist, and fold, making them ideal for applications where space is limited or components must move during use.

This structural adaptability has opened the doors to new design possibilities across industries. Devices such as smartphones, foldable screens, hearing aids, medical implants, and aerospace instruments increasingly rely on Flex PCBs to ensure both functionality and durability in compact and high-performance environments.

Enabling Compact and Lightweight Designs

With consumer demand leaning heavily toward lighter, thinner, and more portable devices, Flex PCBs are naturally suited for the task. Because they can be shaped to fit into confined or irregular spaces, they eliminate the need for bulky connectors and excess wiring. This results in lighter designs with fewer components, reducing both the physical footprint and manufacturing complexity.

For instance, in wearable devices, the combination of lightweight construction and flexibility is vital. Flex PCBs are seamlessly integrated into watch bands, fitness trackers, and even smart clothing, providing reliable performance under constant movement.

Enhanced Reliability in Harsh Conditions

Another significant advantage of Flex PCBs is their ability to withstand harsh environments. Thanks to their inherent vibration resistance, shock tolerance, and wide temperature range capabilities, they are commonly used in automotive and aerospace applications. Unlike rigid boards, which are more prone to connection failures under mechanical stress, Flex PCBs can absorb shocks and maintain integrity in dynamic conditions.

In industries where electronic failure can be catastrophic, such as aviation or critical healthcare monitoring devices, the stability and durability of flexible circuits offer unmatched reliability.

Streamlined Manufacturing and Cost Efficiency

At first glance, the cost of producing Flex PCBs may seem higher than that of rigid boards. However, this is often offset by reductions in assembly time, component count, and wiring complexity. Flex circuits can combine multiple rigid boards and connectors into a single unit, eliminating solder joints and reducing failure points.

Modern flexible PCB fabrication processes enable high levels of precision and customisation, allowing manufacturers to produce tailored solutions with minimal waste. Moreover, automated assembly and testing procedures are easier to implement, contributing to shorter production cycles and improved scalability.

Facilitating Innovation Across Industries

The reach of Flex PCBs goes far beyond consumer electronics. In the medical field, they are used in minimally invasive devices, such as catheters and endoscopes, where flexibility and miniaturisation are essential. In the automotive industry, they support advanced driver-assistance systems and infotainment controls within confined dashboards. Even the military and aerospace sectors incorporate Flex PCBs into guidance systems, satellites, and communication equipment for enhanced performance under extreme conditions.

Leading flex circuit board manufacturers are constantly developing new materials and multi-layer designs to keep pace with demand. Innovations such as rigid-flex hybrids and high-density interconnects (HDIs) are expanding the possibilities even further.

A New Standard for the Future

The momentum behind Flex PCBs suggests that they are not just a trend but a long-term shift in the electronics industry. As devices continue to demand more power, connectivity, and performance in less space, Flex PCBs provide an essential foundation for next-generation technologies.

Moreover, the trend toward sustainability and energy efficiency further supports the use of Flex PCBs. Their ability to reduce material usage and optimise circuit paths contributes to more energy-efficient products and environmentally friendly manufacturing practices.

Blind Buried Circuits, a respected name in the PCB industry, is among the pioneers pushing the boundaries of what’s possible with Flex PCBs. Their expertise in complex circuit design and custom solutions highlights the role of specialised partners in the development process.

Final Thoughts

The rise of Flex PCBs is transforming electronics from the inside out. Their influence is evident in everything from everyday gadgets to critical systems in space exploration. They enable greater functionality, improve reliability, and support innovative design across various sectors.

However, creating a high-quality flex circuit that meets stringent requirements is no simple task. It demands a deep understanding of material properties, mechanical stress management, and precise layout design. This is where expertise becomes crucial.

What's Your Reaction?