How Can Sheet Metal Fabricators Improve Your Production Process

In today’s fast-paced manufacturing world, companies are always looking for ways to improve their production processes. One area that often offers significant improvements is sheet metal fabrication. Whether you are working on a small project or handling large-scale production metal fabrication can streamline your process and deliver better results.

But how exactly can sheet metal fabricators help you improve your production process? Let's take a look at some of the key benefits and how these professionals contribute to faster, more efficient production.

Customized Solutions to Meet Specific Needs

Every manufacturing process has unique requirements, and sheet metal fabricators can help meet those needs by providing tailored solutions. Whether you need parts with specific dimensions, shapes, or materials, a sheet metal contractor can provide custom metal fabrication to ensure that the components fit your design precisely.

Efficiency and Faster Turnaround Times

Time is money, and the quicker your production process runs, the better it is for your bottom line. Sheet Metal Fabricators can help improve your production speed by offering efficient methods such as laser cutting Langley or CNC machining. These advanced technologies help create precise parts with minimal human intervention, reducing the time needed to produce each item.

Laser cutting, in particular, allows for faster and more accurate cutting of metal sheets compared to traditional methods. This ensures that the fabrication process is not only quicker but also delivers high-quality components with fewer errors.

Cost-Effective Production

In the long run, sheet metal fabrication can save your business money. By choosing custom metal fabrication over mass-produced stock parts, you can minimize waste. Fabricators use advanced techniques to make the most out of the materials, ensuring that the sheet metal used is maximized.

Additionally, because the fabrication process is highly efficient, businesses can reduce labor costs and time spent on fixing errors.

Improved Precision and Quality Control

When it comes to manufacturing, precision is key. A single error can result in delays, rework, or even the need to discard parts altogether. Working with experienced metal fabricators ensures that your products are fabricated with the highest level of accuracy. This is crucial for industries like medical device manufacturing, automotive production, and electronics, where every detail matters.

Fabricators often use advanced tools like laser cutters, which can produce parts with exceptional precision. With tight tolerances, your components will be ready to fit perfectly in your final product, minimizing the risk of defects.

Flexibility for Small and Large Runs

Whether you need just a few parts or a large batch, sheet metal fabricators offer flexibility in production runs. Many fabricators are equipped to handle both small and large quantities, making them an ideal choice for businesses that may need to scale production up or down.

Advanced Technologies and Techniques

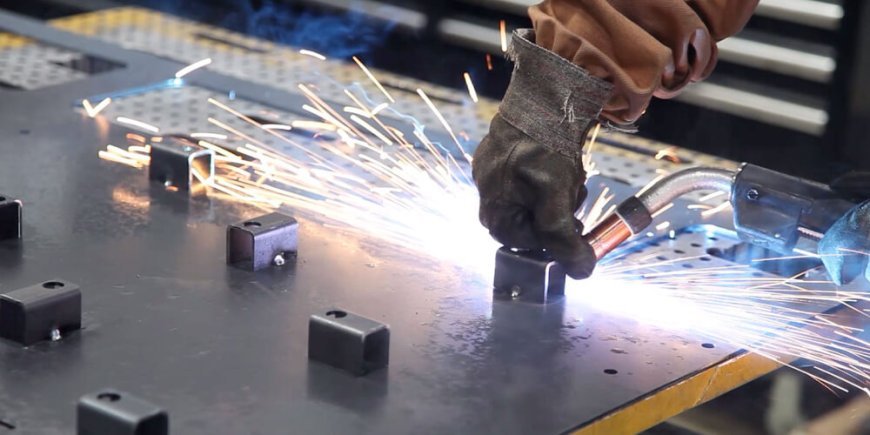

One of the key ways sheet metal fabricators improve production is through the use of advanced technologies. Laser Cutting Langley for example, is one such technique that has revolutionized the fabrication process. Laser cutters use focused light to cut through metal with incredible precision, providing sharp edges and smooth finishes.

Besides laser cutting, other advanced techniques like waterjet cutting, welding, and CNC machining further enhance the quality of the finished product. These technologies not only improve precision but also reduce production time and waste.

Better Material Selection and Strength

The materials you choose for your production process can significantly impact the quality and durability of your final product. Metal fabrication professionals have access to a wide range of materials, including steel, aluminum, copper, and brass, which can be customized to meet the needs of your project.

Fabricators can help you select the right material for your specific application, ensuring that the components are durable, lightweight, and strong enough for their intended purpose.

Prototyping and Design Support

Another area where metal fabricators can assist is in the design and prototyping phase. If you're still in the conceptual phase of a project, fabricators can help create prototypes that allow you to test and refine your design before moving to full-scale production. Prototyping helps you catch potential issues early in the process, saving you time and money.

Reduced Waste and Environmental Impact

Sustainability is becoming increasingly important for many industries. Fortunately, metal sheet fabrication can help reduce waste and minimize the environmental impact of production. With precise cutting and material handling, fabricators can ensure that the materials are used efficiently, resulting in less scrap and fewer discarded parts.

Access to Local Fabricators

Finally, businesses that are searching for “sheet metal fabrication near me” can benefit from working with local fabricators. Local sheet metal contractors can offer personalized services and quicker turnaround times because they’re based in your area. Additionally, working with a local fabricator can reduce shipping costs and lead times, ensuring that your production schedule stays on track.

Conclusion

Sheet metal fabrication plays a crucial role in improving production processes across various industries. From customized solutions and faster turnaround times to cost-effective production and advanced technologies like laser cutting Langley, these fabricators help businesses create high-quality products efficiently.

What's Your Reaction?