How Full Turnkey PCB Helps You Scale Hardware Products

Scaling a hardware product from a prototype into mass production is one of the most complex transitions in the tech industry. While software startups can pivot quickly with agile updates and digital deployments, hardware-focused ventures face significant manufacturing challenges. Among the critical decisions hardware developers must make is how to approach printed circuit board manufacturing. This is where full turnkey solutions come into play.

In the dynamic and fast-paced landscape of electronics development, speed and efficiency are paramount. The journey from proof of concept to product launch can be lengthy if fragmented production methods are used. Every bottleneck—whether in sourcing components, quality assurance, or testing—can delay the launch and impact market competitiveness. Choosing a reliable approach that integrates all stages of PCB production can be a decisive advantage.

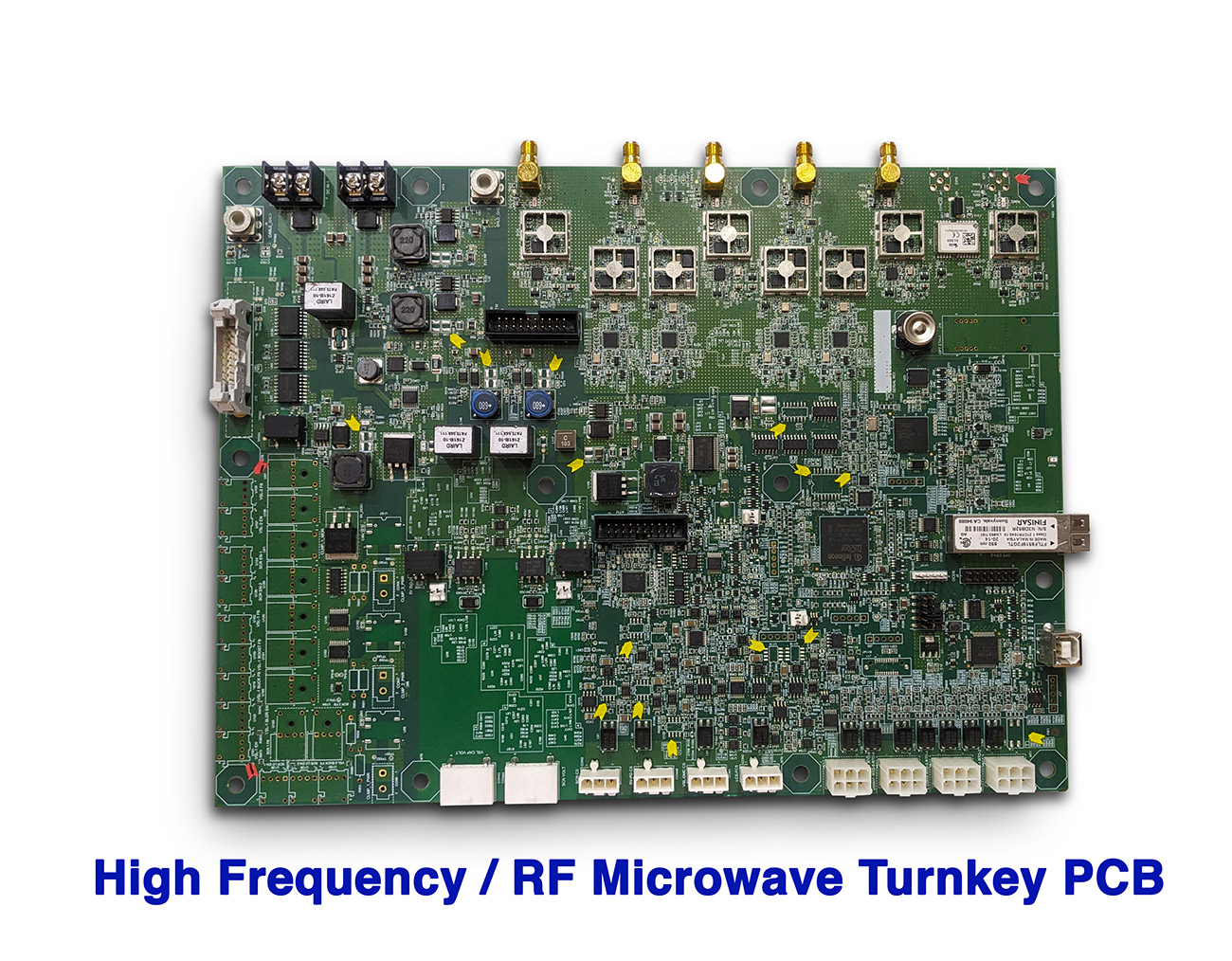

Full turnkey PCB solutions refer to services where a single vendor handles the entire PCB manufacturing and assembly process. This includes design verification, component procurement, fabrication, assembly, quality testing, and delivery. Rather than working with separate vendors for each phase of development, teams benefit from centralized management and streamlined communication.

Key Benefits of Full Turnkey PCB Services

Here are some critical reasons why opting for a full turnkey approach is ideal for scaling hardware products:

-

Simplified Project Management: One point of contact handles the entire production cycle, reducing miscommunication between teams and vendors.

-

Reduced Lead Time: Turnkey vendors streamline procurement and manufacturing steps, helping you bring products to market faster.

-

Improved Quality Control: Quality checks are integrated throughout the process, which increases consistency and product reliability.

-

Cost Transparency: With one vendor managing all elements, it becomes easier to estimate costs and avoid unexpected budget increases.

-

Scalable Production: As demand increases, full-service providers can scale up manufacturing without disrupting timelines.

The primary advantage of this method lies in reducing operational complexity. When companies work with different suppliers for sourcing components, manufacturing PCBs, and assembling them, the risks of miscommunication and delays increase. Small mistakes such as incompatible components or poorly aligned solder masks can require significant rework or even scrapping entire batches. By working with one vendor offering full turnkey pcb, all stakeholders are on the same page from the outset, reducing errors and ensuring better coordination across the lifecycle of product development.

Another key benefit is cost control. Managing multiple suppliers often leads to unforeseen expenses. These could be due to fluctuating component prices, shipment delays, or additional fees for last-minute revisions. A turnkey provider can better forecast total costs since it oversees every element of the project. This predictability enables startups and product teams to plan better, allocate budgets more efficiently, and mitigate financial risks.

Enhancing Time-to-Market Efficiency

In the electronics industry, being the first to deliver a working and reliable product often determines success. Delays can result in missed sales cycles, loss of investor confidence, or a competitor taking the lead. Turnkey providers eliminate long procurement lead times and disjointed supply chains, accelerating the delivery timeline. By handling logistics, inventory, and production internally, they offer a quicker and smoother route to market.

Engineering and Compliance Support

-

Design for Manufacturability (DFM): Engineering teams ensure the design is optimized for mass production.

-

Regulatory Compliance: Turnkey providers often ensure the boards meet international quality and safety standards.

-

Prototyping to Production: Some services allow seamless movement from prototyping to low or high-volume production.

Additionally, companies benefit from having access to experienced engineers and quality assurance professionals. Turnkey service providers typically have specialized teams to conduct DFM reviews, ensure regulatory compliance, and conduct end-to-end testing. This level of support enhances product reliability and helps avoid costly mistakes that could arise from design flaws or incompatible components.

While the technical side of scaling hardware is vital, logistics play an equally important role. One overlooked benefit of full turnkey pcb assembly is centralized logistics management. Rather than shipping PCBs across different regions for assembly, testing, and packaging, all steps are completed within a single ecosystem. This not only reduces transportation costs and carbon footprint but also limits the chances of damaged goods during transit.

Resilient Supply Chains and Vendor Networks

Recent global disruptions have underscored the importance of having strong supply chain partners. Full turnkey providers often have long-standing relationships with component suppliers, which can translate into priority access during shortages. Additionally, their ability to pivot and source alternatives quickly can save companies from prolonged delays.

Freeing Up Internal Resources

For hardware developers focused on scaling—particularly startups with limited bandwidth and resources—outsourcing PCB production and assembly can free up internal teams to concentrate on:

-

Product innovation

-

Customer experience

-

Branding and market entry

-

Software integration

-

Strategic business development

Instead of getting bogged down in procurement tasks or dealing with manufacturing setbacks, teams can focus on growth and customer satisfaction.

Interestingly, even companies from unrelated sectors have recognized the significance of leveraging efficient PCB solutions. For instance, Blind Buried Circuits, a business rooted in dependable plumbing services relies heavily on various electronic components in modern tools and smart systems. The quality and reliability of these components often depend on expertly produced PCBs that can handle operational demands.

As technology continues to evolve, the expectations around electronic products are increasing. Devices are expected to be faster, smarter, more reliable, and more affordable. Meeting these expectations requires not just innovation in design but also excellence in execution. Full turnkey solutions offer a scalable and strategic approach to manufacturing, one that aligns with the demands of modern hardware production.

Final Thoughts

Scaling hardware products is a multifaceted challenge that goes beyond simply increasing production volumes. It requires a cohesive, efficient, and quality-focused approach to PCB manufacturing. By opting for a full turnkey PCB service, companies can streamline development, control costs, reduce errors, and accelerate their time-to-market. Whether you’re launching a groundbreaking consumer gadget or upgrading industrial tools with smart capabilities, turnkey PCB solutions can be the bridge between idea and scalable product success.

What's Your Reaction?