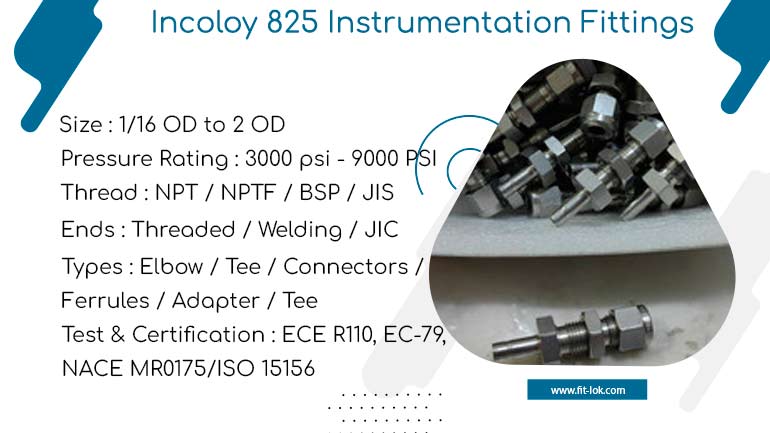

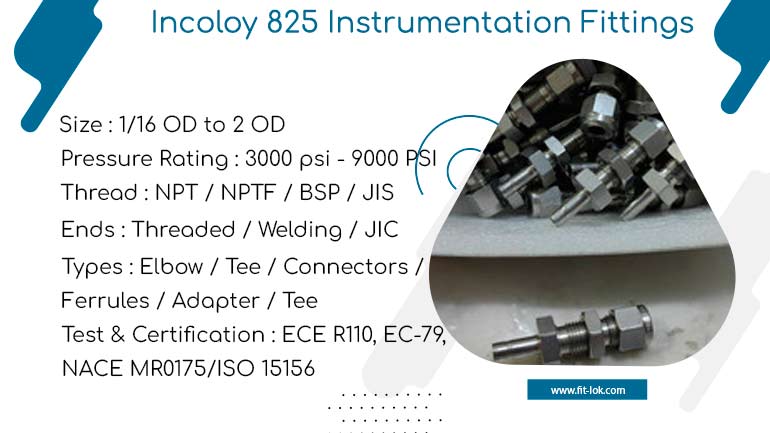

Incoloy 825 Instrumentation Fittings

What's Your Reaction?

TigerBookwork Jul 19, 2025 8

TigerBookwork Jul 19, 2025 8

rahul kumar Jul 23, 2025 0

asas Feb 2, 2025 31

rahul kumar Jul 23, 2025 0

Join our subscribers list to get the latest news, updates and special offers directly in your inbox

Incoloy 825 Instrumentation Fittings: A Comprehensive Overview

High-performance alloy Incoloy 825 is a multipurpose substance renowned for its superior mechanical and corrosion resistant qualities. Incoloy 825 is widely utilized in demanding industrial settings and is especially preferred for instrumentation fittings, which are essential in systems that need precise measurement and control. The qualities, uses, and advantages of Incoloy 825 instrumentation fittings will be discussed in this article, with a focus on how they contribute to dependable and safe operations in challenging industries.

Nickel, chromium, iron, molybdenum, and copper are all present in considerable amounts in Incoloy 825, an alloy based on nickel. These components work together to give Incoloy 825 its exceptional resistance to corrosion, especially in areas that contain acids, alkalis, and other corrosive materials. The alloy is perfect for use in sectors like chemical processing, oil and gas, nuclear power, and marine settings because it is also resistant to stress corrosion cracking.

The key elements in Incoloy 825 and their benefits include:

These elements give Incoloy 825 its ability to withstand corrosion, heat, and mechanical stress, making it a reliable choice for instrumentation fittings.

Fittings for instruments are crucial parts of control systems that keep an eye on and manage industrial operations. In order to enable accurate measurement and control of factors like pressure, temperature, and flow rate, these fittings are commonly employed to connect instruments to pipelines, valves, or other equipment. Particularly in corrosive settings, the material selection for instrumentation fittings is essential to guaranteeing precise readings, lifespan, and safety.

Incoloy 825 instrumentation fittings are commonly used in the following industries:

Incoloy 825 instrumentation fittings are used for a variety of functions, including:

Instrumentation fittings made of Incoloy 825 are an essential part of contemporary industrial systems, offering vital assistance for control and instrumentation operations. They are the go-to option for sectors where accuracy, dependability, and safety are crucial because to their mechanical strength, resistance to corrosion, and stability at high temperatures. Whether utilized in power generation facilities, offshore rigs, or chemical plants, Incoloy 825 consistently demonstrates its value as a robust, reasonably priced material for intricate instrumentation applications.

bloomfield Jan 9, 2025 430

Abbas Imran Jan 10, 2025 374

Abbas Imran Jan 10, 2025 372

HCT Containers May 1, 2025 364

Abbas Imran Jan 10, 2025 346