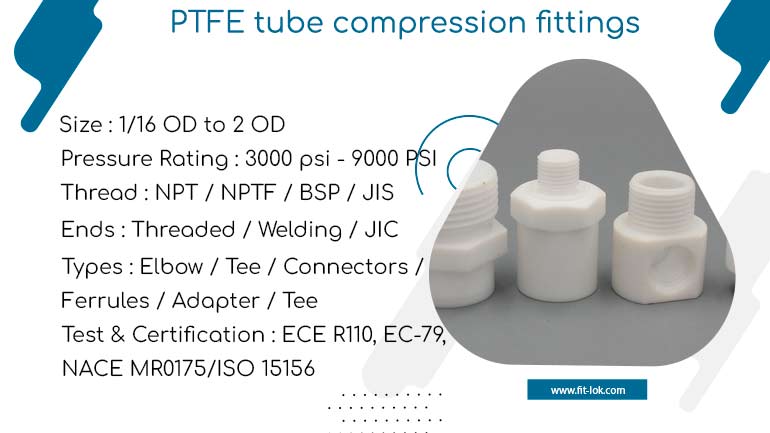

PTFE tube compression fittings

PTFE Tube Compression Fittings: Everything You Need to Know

PTFE (Polytetrafluoroethylene) tube compression fittings are vital components in various industrial applications, providing secure and leak-proof connections in fluid and gas systems. PTFE, often recognized by the brand name Teflon, is known for its chemical resistance, high-temperature tolerance, and low friction properties, making it ideal for use in demanding environments.

In this article, we’ll explore what PTFE tube compression fittings are, their benefits, applications, installation process, and key considerations when selecting them.

What Are PTFE Tube Compression Fittings?

Compression fittings are mechanical devices used to join tubes, usually to a fitting or connector, creating a tight, leak-free seal. PTFE tube compression fittings are specifically designed for use with PTFE tubing, a type of plastic tube with excellent properties, such as low surface friction, high resistance to corrosion, and high dielectric strength.

These fittings work by compressing a ferrule (a small metal ring) onto the outside of the PTFE tube and into a receiving fitting. The compression creates a tight seal that prevents leaks and ensures a secure connection even under varying pressures and temperatures.

Why Choose PTFE Tube Compression Fittings?

1. Chemical Resistance

PTFE tubing, when used with compression fittings, offers unparalleled resistance to a wide variety of chemicals, including strong acids, alkalis, and solvents. This makes it an excellent choice for industries where fluid contamination must be avoided, such as the pharmaceutical, food processing, and chemical industries.

2. Temperature Resistance

PTFE has a wide operating temperature range, typically from -200°C to +260°C, allowing PTFE tube compression fittings to perform effectively in both very hot and very cold environments. This feature makes them particularly useful in applications involving steam, hot gases, and cryogenic systems.

3. Leak-Free Connections

Compression fittings ensure a tight seal when installed correctly, preventing leaks in high-pressure systems or systems carrying dangerous fluids. The compression process locks the ferrule in place, ensuring the PTFE tubing stays firmly in position.

4. Easy Installation

PTFE tube compression fittings are relatively easy to install. They require minimal tools and can be fitted without specialized equipment. This ease of installation reduces labor costs and downtime during maintenance or system assembly.

5. Versatility

These fittings come in various types, sizes, and configurations, making them adaptable to different applications. Whether for gas lines, hydraulic systems, or chemical processes, PTFE tube compression fittings can meet the demands of a wide range of industries.

Applications of PTFE Tube Compression Fittings

Due to their excellent properties, PTFE tube compression fittings are used across various industries and applications, including:

-

Chemical Processing PTFE tube compression fittings are commonly used in chemical processing plants where highly corrosive substances need to be transported. Their resistance to aggressive chemicals ensures that systems remain intact and safe, reducing the risk of contamination.

-

Pharmaceutical and Biotech Industries In industries like pharmaceuticals and biotechnology, the purity of fluids and gases is crucial. PTFE’s non-reactive nature makes it ideal for conveying sensitive materials, ensuring there’s no contamination during the manufacturing process.

-

Food and Beverage Industry PTFE tubing and compression fittings are widely used in food and beverage processing due to their compliance with FDA regulations and their resistance to food-grade chemicals. They ensure safe transport of food products and ingredients without risk of contamination.

-

Electronics Manufacturing The dielectric properties of PTFE make it ideal for use in the electronics industry. PTFE tube compression fittings are used in systems where high-voltage conductors need to be insulated or where systems need to be protected from electrostatic interference.

-

Oil and Gas The oil and gas industry uses PTFE tube compression fittings in systems involving high-pressure fluids or gases, particularly where corrosion and leaks are a concern. PTFE ensures a long lifespan and a safe environment.

-

Hydraulic and Pneumatic Systems PTFE tube compression fittings are used in hydraulic and pneumatic systems where pressure control is crucial. They ensure secure and durable connections that can withstand fluctuating pressures.

Installation of PTFE Tube Compression Fittings

The installation of PTFE tube compression fittings requires attention to detail to ensure a leak-free and secure connection. Below are the basic steps involved:

-

Cut the PTFE Tube: Use a sharp tube cutter to ensure a clean, square cut on the PTFE tube. This step is important for the compression fitting to seal properly.

-

Prepare the Compression Fitting: Place the nut and ferrule onto the tube before inserting the tube into the fitting. The ferrule should be positioned around the tube, and the nut should be threaded onto the fitting.

-

Tighten the Nut: Tighten the nut onto the compression fitting by hand and then use a wrench to tighten it further. This action compresses the ferrule, which creates a secure seal between the tube and the fitting.

-

Check for Leaks: After installation, test the system by running fluids or gases through the tube. If there’s no leakage, the installation was successful.

Considerations When Choosing PTFE Tube Compression Fittings

When selecting PTFE tube compression fittings, consider the following factors:

- Compatibility: Ensure the fittings are compatible with the PTFE tube size and material specifications.

- Pressure Rating: Verify that the compression fittings can handle the pressure levels of the system.

- Temperature Range: Make sure the fittings are suitable for the temperature conditions in your application.

- Corrosion Resistance: Check that the materials of the fitting can resist corrosion, particularly if used with harsh chemicals.

- Ease of Installation: Choose fittings that are easy to install and maintain to reduce operational downtime.

Conclusion

PTFE tube compression fittings offer a reliable and efficient solution for various industrial applications, from chemical processing to food safety. Their ability to provide leak-free connections, combined with resistance to high temperatures, chemicals, and wear, makes them invaluable in many industries. When selecting these fittings, it is essential to consider the compatibility, pressure, temperature, and material properties to ensure optimal performance. By understanding their features and applications, you can ensure that PTFE tube compression fittings will meet the demands of your specific systems.

What's Your Reaction?