The Advantages of Using Titanium Ball Valves in High-Pressure Applications

Advantages of Using Titanium Ball Valves in High-Pressure Applications

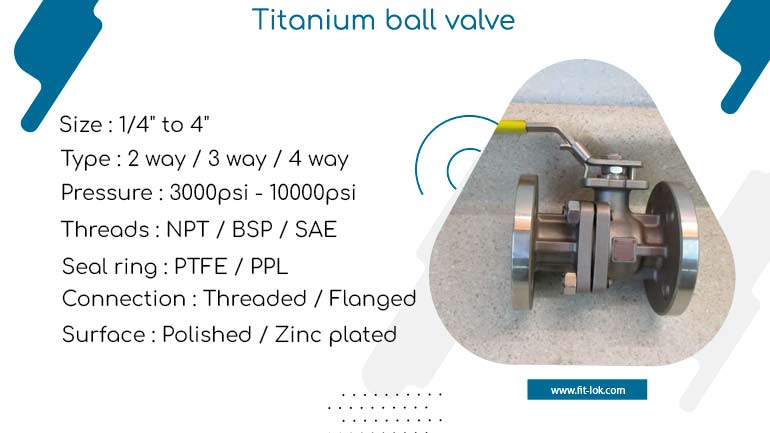

In industries where high-pressure applications are frequent, titanium ball valves are growing in popularity. Because of their special qualities, they are a great option for demanding settings that call for performance, durability, and corrosion resistance. Titanium is perfect for regulating fluid flow in systems under high pressure because of its remarkable corrosion resistance and strength-to-weight ratio. The main benefits of employing titanium ball valves in high-pressure applications will be discussed below.

1. Exceptional Corrosion Resistance

Titanium ball valves' unmatched corrosion resistance is one of their main benefits. The protective oxide coating that titanium naturally produces on its surface keeps the metal from interacting with strong chemicals, saltwater, and other materials. Because of this characteristic, titanium is the perfect material for high-pressure applications in sectors where exposure to corrosive fluids is frequent, like chemical processing, offshore oil and gas production, and desalination plants. Long-lasting performance and fewer valve replacements are ensured by titanium's resistance to corrosion and degradation, especially in harsh conditions, in contrast to other materials like stainless steel.

2. High Strength-to-Weight Ratio

Titanium's exceptional strength-to-weight ratio is well known. It is a great material for situations where both strength and weight are important because it is much lighter than many other metals while yet being stronger than many others. Valves in high-pressure systems need to be able to sustain significant forces without making the system unnecessarily heavy. The perfect strength-to-weight ratio provided by titanium ball valves guarantees that the valve can withstand high pressure situations without placing an excessive amount of strain on the system's constituent parts. This is especially helpful in sectors like high-performance engineering, oil and gas, and aerospace where it's critical to reduce weight without sacrificing strength.

3. High-Temperature Resistance

Ball valves made of titanium function remarkably well in hot conditions. Titanium is suited for high-pressure applications involving high temperatures since it can tolerate temperatures of up to 600°C (1,112°F) without compromising its structural integrity. In sectors like chemical processing and power generation, where high-pressure systems frequently function in extremely hot or cold environments, this heat resistance is crucial. Even in the most extreme circumstances, the valve's dependability and lifespan are guaranteed by titanium's capacity to retain its strength and resistance to oxidation at high temperatures.

4. Improved Leak Tightness

Ball valves are known for their ability to provide tight shut-off in fluid systems, and when made from titanium, their leak-tightness is further enhanced. Titanium's ability to withstand high pressures and aggressive chemicals ensures that the seals on titanium ball valves are less likely to degrade over time. This improved leak tightness is crucial in high-pressure applications, where even minor leaks can result in hazardous conditions, environmental damage, or equipment failure. Titanium ball valves offer a high level of security in maintaining a leak-free system, thus improving operational safety and efficiency.

5. Long Lifespan and Reduced Maintenance Costs

The combination of titanium's corrosion resistance, high strength, and durability means that titanium ball valves have a much longer lifespan than valves made from other materials. In high-pressure systems, where frequent valve replacements can result in significant downtime and increased maintenance costs, titanium ball valves reduce the need for frequent maintenance. Their ability to resist wear, corrosion, and temperature-related degradation results in fewer failures and a reduced need for replacement, saving both time and money in the long run. The reduced maintenance needs also contribute to the overall efficiency and reliability of high-pressure systems.

6. Non-Magnetic Properties

Titanium is non-magnetic, which can be crucial in certain high-pressure applications, especially in industries like nuclear power or aerospace, where magnetic interference can disrupt sensitive equipment. Non-magnetic valves eliminate the risk of unwanted electromagnetic interference, ensuring that systems function optimally. This feature is also beneficial in applications that involve the use of magnetic fields or where the presence of magnetism can affect the performance of other equipment in the system.

7. Resistance to Fatigue and Stress Cracking

High-pressure systems can experience cyclical stresses, which can lead to fatigue and stress cracking in valves made from less durable materials. Titanium ball valves are highly resistant to these types of failures due to titanium’s remarkable ability to withstand cyclic loading and stress over extended periods. This resistance to fatigue makes titanium ball valves ideal for industries that require valves to operate continuously under high pressure, such as in chemical reactors, oil and gas pipelines, or high-pressure hydraulic systems.

8. Environmental Impact and Sustainability

Titanium is a sustainable material. It is non-toxic and environmentally friendly, making it a suitable choice for industries that aim to reduce their environmental footprint. Unlike some metals that can release harmful substances during manufacturing or operation, titanium is inert and poses minimal risk to the environment. This is an important consideration in industries such as water treatment, where systems need to meet strict environmental standards while still providing robust performance.

Conclusion

In conclusion, titanium ball valves offer numerous advantages for high-pressure applications. Their exceptional corrosion resistance, high strength-to-weight ratio, ability to withstand high temperatures, improved leak-tightness, long lifespan, and reduced maintenance costs make them an ideal choice for industries that require reliable and durable valve solutions. Whether in chemical processing, oil and gas production, aerospace, or other high-pressure environments, titanium ball valves provide the performance and longevity needed to ensure efficient, safe, and cost-effective operations. With their growing popularity, titanium ball valves are poised to play a key role in the future of high-pressure systems.

What's Your Reaction?