Understanding Duplex Ball Valves: A Comprehensive Guide

Understanding Duplex Ball Valves: A Comprehensive Guide

In many industrial applications, duplex ball valves are key parts that offer dependable flow control in systems where robustness and performance in harsh environments are crucial. These valves are especially well-known for their very accurate fluid flow control, which provides benefits including corrosion resistance, high pressure handling, and effective maintenance procedures. We will examine the definition of duplex ball valves, their operation, advantages, and applications in many industries in this guide.

What is a Duplex Ball Valve?

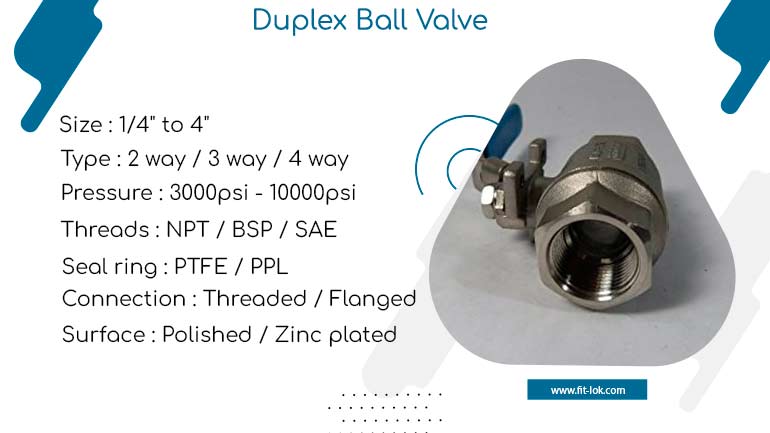

A revolving ball inside the valve body controls the flow of liquids or gases in a duplex ball valve, a form of ball valve with a two-way or three-way construction. The word "duplex" describes the usage of duplex stainless steel, a crucial component, in the valve body's manufacture. The alloy known as duplex stainless steel, which combines ferritic and austenitic structures, gives the valve its better mechanical qualities, including increased strength, resistance to corrosion, and resistance to stress corrosion cracking.

How Duplex Ball Valves Work

Duplex ball valves operate similarly to standard ball valves, utilizing a spherical ball with a hole in the center that rotates to control the flow. The valve is typically installed in pipelines where the flow of a fluid or gas needs to be started, stopped, or diverted.

-

Two-Way Duplex Ball Valve: The most common type, a two-way duplex ball valve, features a ball with a hole that, when aligned with the inlet and outlet ports, allows fluid to pass through. When the valve is turned, the ball rotates, obstructing the flow and stopping it completely.

-

Three-Way Duplex Ball Valve: A three-way valve has a ball with more than one port, allowing the valve to divert flow from one source to another, making it suitable for applications where the flow needs to be directed to multiple destinations.

The valve is typically controlled by a handle or an actuator, which rotates the ball to open or close the passageway. The actuator can be manual, pneumatic, or electric, depending on the application.

Benefits of Duplex Ball Valves

-

Corrosion Resistance: Duplex stainless steel offers superior resistance to both pitting and crevice corrosion, making it ideal for use in aggressive environments where regular stainless steel may degrade.

-

Strength and Durability: Duplex ball valves are built to withstand high-pressure and high-temperature conditions, providing reliability in challenging operating environments.

-

Improved Performance: The design of duplex ball valves allows for precise flow control, reducing the likelihood of leaks and enhancing system efficiency.

-

Long Service Life: The robustness of duplex stainless steel and the simple design of the valve ensure a long service life with minimal maintenance, leading to reduced downtime and lower maintenance costs.

-

Ease of Maintenance: Duplex ball valves are easy to maintain due to their straightforward design. Many have a full-bore opening that allows easy inspection and cleaning.

Applications of Duplex Ball Valves

-

Oil and Gas Industry: In this sector, duplex ball valves are commonly used in the transportation of crude oil and natural gas, where they resist corrosion from hydrogen sulfide, saltwater, and other harsh chemicals.

-

Chemical Processing: The chemical industry often deals with corrosive fluids and gases. Duplex ball valves are ideal for controlling flow in systems where acids, alkalis, or other reactive substances are handled.

-

Water Treatment: For both municipal and industrial water treatment systems, duplex ball valves provide the durability needed to handle aggressive chemicals and high-pressure water systems.

-

Marine Applications: Duplex ball valves are often used in shipbuilding and other marine applications, where the valves resist corrosion from seawater.

-

Power Generation: In power plants, especially those using steam or gas turbines, duplex ball valves are used for controlling the flow of steam, water, or cooling fluids, ensuring safety and system efficiency.

Conclusion

Duplex ball valves are an essential part of industries that need excellent performance, corrosion resistance, and durability. These valves, which are made of duplex stainless steel, are perfect for use in water treatment, chemical processing, oil and gas, and other fields because of their remarkable strength and resilience to extreme conditions. Duplex ball valves are an invaluable component of any industrial system because of their dependable and effective performance, which guarantees a long service life, simple maintenance, and reduced downtime.

What's Your Reaction?