What is a PTFE Needle Valve and Why is it Important?

What's Your Reaction?

Seoexpert Shaikh Jul 26, 2025 4

pantherbookwb Jul 30, 2025 10

TigerBookwork Jul 26, 2025 8

TigerBookwork Jul 25, 2025 8

Charles Boult Jul 7, 2025 12

Join our subscribers list to get the latest news, updates and special offers directly in your inbox

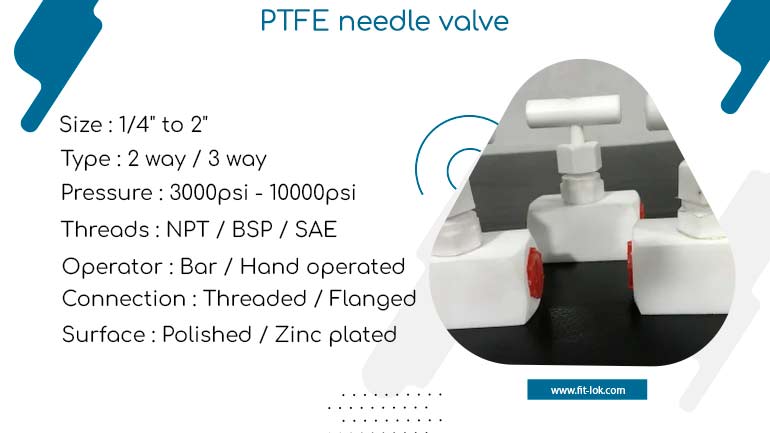

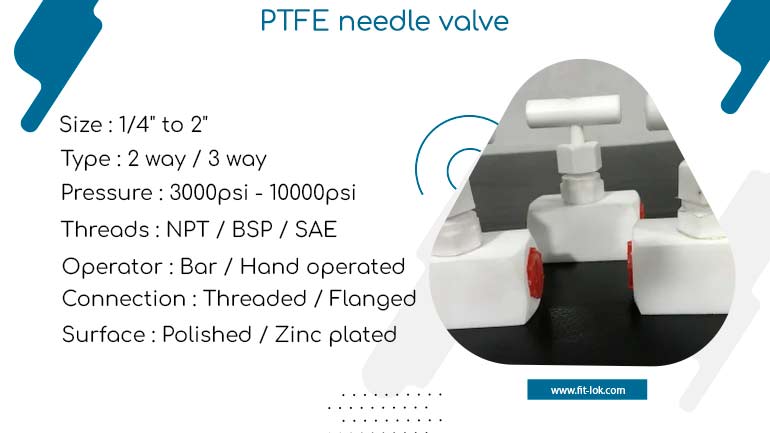

A PTFE needle valve is a type of valve used to precisely control the flow of liquids or gases within a system. These valves are often designed with a needle-shaped spindle that allows for fine adjustments to the flow rate, making them ideal for applications where precise flow control is essential. The term “PTFE” refers to the material the valve body and sometimes the seal are made of—polytetrafluoroethylene—a high-performance plastic renowned for its chemical resistance and durability.

The core component of a needle valve is the needle stem, which is threaded into the valve seat. By rotating the stem, the needle moves closer to or further away from the seat, thereby regulating the flow of the fluid. This design allows for extremely fine flow control compared to other types of valves, which can be crucial in applications where even slight fluctuations in flow could cause problems or inefficiency.

In a PTFE needle valve, the valve body, stem, and often the seat are made of PTFE, ensuring high chemical resistance, particularly to aggressive chemicals or highly reactive substances. The PTFE material helps maintain the valve's integrity and performance even in extreme temperatures, and it also provides excellent resistance to corrosion. This makes PTFE needle valves ideal for industries dealing with aggressive chemicals, high temperatures, or harsh environments.

Precise Flow Control Needle valves are designed for fine flow regulation, offering precision adjustments that are necessary in laboratory experiments, chemical processing, and pharmaceutical production. In many applications, controlling the flow of a substance down to small increments is crucial to achieving consistent results, maintaining system pressure, and avoiding over or underfeeding.

PTFE needle valves excel in this capacity, ensuring that fluid or gas flows at a constant rate with minimal fluctuation. This level of accuracy is not as easily achievable with larger or more basic valve types.

Chemical Compatibility PTFE is one of the most chemically resistant materials available, making it ideal for applications involving strong acids, solvents, or corrosive liquids. Traditional metal valves can corrode or degrade when exposed to these substances over time, compromising the integrity of the system and creating potential safety hazards. The non-reactive nature of PTFE ensures the valve will not affect the fluid flow, even when the system contains harsh chemicals.

Industries like pharmaceutical manufacturing, chemical processing, and oil & gas exploration rely on PTFE needle valves because they are guaranteed to last and maintain performance even in the most chemically aggressive environments.

Temperature Resistance PTFE materials are known for their ability to withstand high temperatures without degrading. This property is vital in industries where the fluid or gas passing through the valve can reach extreme temperatures, such as in steam systems, high-temperature chemical processes, or even in heat exchangers. The high temperature resistance of PTFE needle valves ensures their longevity and reliable performance.

Leak-Free Operation Due to the nature of the PTFE material, PTFE needle valves are designed to provide leak-free operation, which is a crucial aspect when working with toxic or pressurized fluids. The tight seal formed by the PTFE material helps to prevent leaks and minimize the risk of contamination in sensitive environments. This is particularly important in systems dealing with dangerous chemicals or in vacuum systems, where even the smallest leak could be problematic.

Durability PTFE needle valves have an exceptionally long lifespan. The material is resistant to wear and tear, which is essential for maintaining continuous operations in industries that require 24/7 reliability. The PTFE valves are not affected by scale buildup, corrosion, or other factors that might damage traditional valve materials. This durability reduces the need for frequent replacements, leading to lower maintenance costs and higher efficiency in industrial settings.

Versatility PTFE needle valves can be used in a wide range of applications. While they are often used in chemical, pharmaceutical, and laboratory settings, they are also beneficial in food processing, biotechnology, and oil and gas operations. The versatility of these valves is due to their resistance to a broad spectrum of materials, and their ability to handle various pressures, flows, and temperatures.

Chemical and Pharmaceutical Processing: When dealing with corrosive and reactive substances, PTFE needle valves offer secure, leak-proof, and precise control to ensure that the flow of chemicals or gases is handled safely and efficiently.

Laboratories: In laboratory environments where precision and safety are paramount, PTFE needle valves allow for precise fluid management, making them perfect for titration or other experimental processes where small adjustments are necessary.

Oil and Gas Industry: PTFE needle valves are often used in this industry because of their resistance to high pressures and harsh substances, ensuring safe flow control in pipelines and gas lines.

Water Treatment: In water purification systems, where chemical dosing needs to be precise, PTFE needle valves offer the reliability and accuracy required.

In summary, PTFE needle valves are crucial components in various industries where precise flow control, chemical resistance, and durability are required. Their design allows for fine adjustments, making them suitable for applications ranging from laboratory experiments to industrial processing. With their ability to withstand harsh chemicals and high temperatures, PTFE needle valves provide a secure, durable, and reliable solution for flow regulation, ensuring safety and efficiency in even the most demanding environments.

bloomfield Jan 9, 2025 443

Abbas Imran Jan 10, 2025 382

Abbas Imran Jan 10, 2025 380

HCT Containers May 1, 2025 371

Abbas Imran Jan 10, 2025 353