Understanding Camlock Couplings: A Beginner’s Guide

Understanding Camlock Couplings: A Beginner’s Guide

In fluid transfer systems, camlock couplings—also referred to as cam and groove couplings—are a typical kind of quick-connect coupling. These couplings are made to attach and disengage quickly and easily without the use of difficult procedures or any tools. Because of this, they are a great option for companies that handle liquids, gasses, and powders, whether they are dangerous or not. They are employed in many different industries, including as water treatment, chemicals, oil & gas, and agriculture.

What Are Camlock Couplings?

Mechanical devices called camlock couplings are used to connect two hoses, pipelines, or tubes so that materials or fluids can be transferred. A male adapter and a female coupler make up the connection, which has a special mechanism that secures the two components together. A basic locking pin controls a group of cam arms that make up the mechanism. A safe, leak-proof connection is created when the cam arms are inserted into the female coupler's grooves.

Components of a Camlock Coupling

A standard camlock coupling features several key components:

- Male Adapter: This part connects to the hose or pipe and fits into the female coupler.

- Female Coupler: The part that receives the male adapter, creating the connection.

- Cam Arms: These arms are the locking mechanism of the coupling. They are engaged and locked over the male adapter to form a tight seal.

- Pins: Pins are inserted into the cam arms to lock them in place, preventing accidental disconnections.

- O-Ring: Positioned on the male adapter or inside the female coupler, the O-ring helps to create a tight, leak-resistant seal between the two parts.

Types of Camlock Couplings

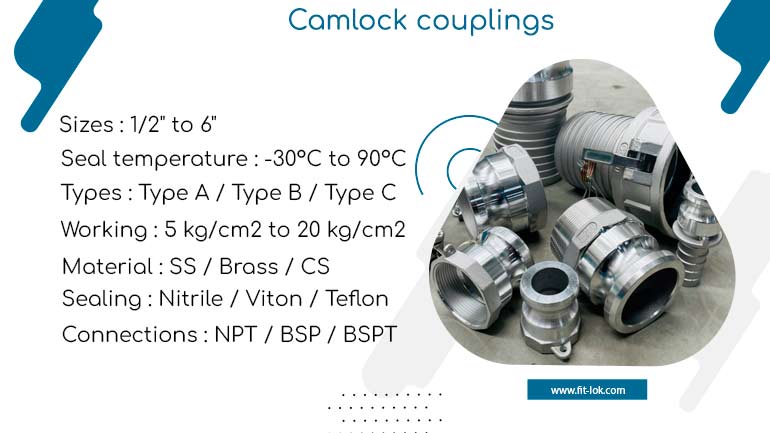

Camlock couplings come in several different configurations, which vary in terms of materials, sizes, and coupling types. The main types of camlock couplings include:

- Type A: This is a male adapter with a female threaded end, designed for a threaded connection.

- Type B: This is a female coupler with a male threaded end, used for threaded connections.

- Type C: A male adapter with a male hose barb fitting, suitable for securing hoses with clamps.

- Type D: A female coupler with a female hose barb fitting, also used for hose connections.

- Type E: A male adapter with a female NPT (National Pipe Thread) fitting, commonly used in applications where a threaded connection is needed.

- Type F: A female coupler with a female NPT fitting.

The choice of type depends on the application and whether the connection needs to be threaded, barbed, or clamp-based.

Materials Used in Camlock Couplings

Camlock couplings are made from a variety of materials, each suitable for different types of applications:

- Aluminum: One of the most common materials, aluminum camlocks are lightweight, durable, and resistant to corrosion, making them suitable for many industries.

- Stainless Steel: Stainless steel couplings are highly durable, resistant to corrosion, and ideal for use in industries dealing with chemicals, oils, or high temperatures.

- Brass: Brass camlocks are corrosion-resistant and offer a durable connection for a range of applications.

- Plastic: Plastic camlock couplings are lightweight, cost-effective, and ideal for handling non-corrosive fluids.

- Ductile Iron: Ductile iron camlocks are used in heavy-duty applications where higher strength and resistance to wear and tear are required.

How to Use Camlock Couplings

Using a camlock coupling is simple and efficient. Here's how:

- Align the Male Adapter and Female Coupler: Place the male adapter into the female coupler, ensuring that the cam arms are in the open position.

- Engage the Cam Arms: Once the parts are aligned, pull the cam arms over the male adapter and into the grooves. Ensure that each cam arm is securely locked in place.

- Insert the Pins: Insert the locking pins into the holes of the cam arms to secure them and prevent accidental disconnection.

- Check for Leaks: After the coupling is engaged, check the connection to ensure it’s leak-proof and secure before starting the fluid transfer process.

Benefits of Camlock Couplings

Camlock couplings offer a range of benefits that make them the preferred choice in many industries:

- Quick Connection and Disconnection: The design of camlock couplings allows for fast and easy connections, saving time and reducing the need for tools.

- Versatility: Camlock couplings come in various sizes and materials, making them versatile and adaptable to a wide range of applications.

- Leak Resistance: The O-ring seal ensures a tight, leak-proof connection.

- Durability: The materials used in camlock couplings (such as stainless steel and aluminum) make them durable and able to withstand harsh environments.

- Safety: The secure locking mechanism reduces the risk of accidental disconnections during fluid transfer, minimizing spills and accidents.

Conclusion

Camlock couplings provide a dependable, safe, and effective way to join hoses and pipes, making them a vital tool for fluid management. These couplings can be utilized in practically any fluid or material transfer application because they come in a wide range of materials and types. They are an essential part of numerous sectors due to their durability, adaptability, and ease of use. Camlock couplings offer a safe, leak-proof connection for all of your fluid transfer requirements, whether you're working with gas, oil, chemicals, or water.

What's Your Reaction?